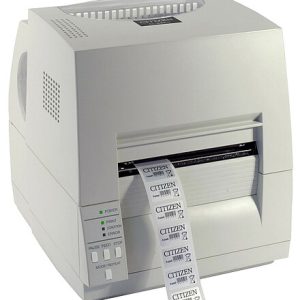

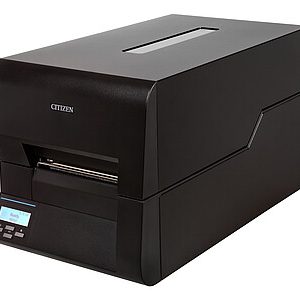

Specifications

| Printing Technology | Thermal Transfer + Direct Thermal |

| Resolution |

|

| Print Width (maximum) | 4 inches (104 mm) |

| Media type | Roll or fanfold media; die-cut, continuous or perforated labels, tags, tickets. Inside or outside wound |

| Media Width (min to max) | 1 – 4.6 inches (25.4 – 118 mm) |

| Media Thickness (min to max) | 63.5 to 254 µm |

| Media Length (min to max) | 0.25 to 64 inches (6.35 to 1625.6 mm) |

| Roll Size (max), Core Size | Outside diameter 8 inches (200mm) Core size 1 to 3 inches (25 to 75 mm) |

| Ribbon size | 3.4 inches (86.5 mm) maximum outside diameter. 450 metres length. |

| Ribbon winding & type | Ink side in or out, automatically sensing. Wax, Wax/Resin or Resin Type |

| Ribbon system | ARCP™ automatic ribbon tension adjustment |

| Mechanism | Hi-Lift™ metal mechanism with wide opening head |

| Media Sensor | Fully adjustable gap, notch and reflective black mark |

| Main Interface | Triple interface: USB and Ethernet built-in plus interface card slot for optional card |

| Optional interfaces |

|

| Case | Hi-Open™ metal case with safe, soft-close feature |

| Control panel | 2 buttons, colour LCD panel with touch control |

| RAM (standard Memory) | 256MB total |

| Drivers and software | Free-of-charge from website, including support for various platforms |

| Emulations (Languages) |

|

| Size (W x D x H) and Weight |

|

| Warranty | 2 years on printer. 6 months or 50 Kms printhead |

Additional Information

| Paper exit | Front exit – prevents damage from moisture or foreign objects |

|---|---|

| Paper Width | Variable paper width – 1 inch (25.4 mm) – 4.6 inches (118.1 mm) |

| Paper load | Front access for all operations including media and ribbon changing |

| Printing Speed | Ultra fast print out – up to 250mm per second (10 inches per second) |

| Media support | Very large media capacity – holds rolls up to 8 inches (200 mm) |

| Ribbon options | Wide range of ribbon options – Uses up to 450 metres inside and outside wound ribbons |

| Paper thickness | Paper thickness up to 0.250mm |

| Front Loading Rewinder for easy rewinding of the backing paper when printing in “peel mode” or when printing batches of labels. | |

| Display: Backlight LCD control panel for easy configuration | |

| Power switch located in recess at front of printer | |

| Hi-Open™ case for vertical opening, no increase in footprint and safe closing. | |

| Low space requirement – integrated power supply enables clean work station | |

| No more unreadable labels – the ARCP™ ribbon control technology assures clear prints. | |

| Media sensor | 1.Label gap sensor 2.Black mark sensor 3.Adjustable media sensor |

| Energy | Internal power supply for reliability |

| Tear bar | Standard tear-bar for perforated tags |

| Front mounted host USB connection for peripherals and memory sticks |

Learn more

Accessories And Options

- Basic peeler

- High speed cutter

- Heavy duty rotary cutter

Operating Systems

- Windows 7 & 10

- Windows Server 2012, 2016 & 2019

- Linux and Mac OS/X

- Zebra® ZPL2®

- Cross-Emulation™ – Automatically switch between Zebra® ZPL® and Datamax®

- BASIC Interpreter – for data stream processing

- Linux CUPS

- Datamax® DMX

- EPL2 Emulation

- Windows 11

- Windows Server 2022

Applications

- Healthcare

- Rental / Hiring

- Manufacturing

- Warehousing

- Retail

There are no reviews yet.